The 4th Industrial Revolution: How to Prepare for the Data-Driven Supply Chain

The data revolution has transformed supply chain management into the most effective way for companies to improve efficiency and reduce costs.

Supply chains have undergone a major evolution since they became a focal point in the 1980s. Automation technologies — and the ability to collect and utilize information about processes and time — have transformed supply chain management into data-driven operations.

The Geodis World Supply Chain Survey found that 57 percent of companies believe enhancing supply chain management gives them a competitive edge in their industries. In fact, Amazon’s tracking, use of, and response to supply chain analytics is one of the reasons why it became one of the largest companies in the world, known both for its efficiency and revenue.

The Benefits of Data

As technology allows more transactions and processes to be tracked and quantified, manufacturers and distributors can take advantage of an unprecedented opportunity to understand and improve their operations.

The primary benefits of supply chain data are:

Supply Chain Visibility

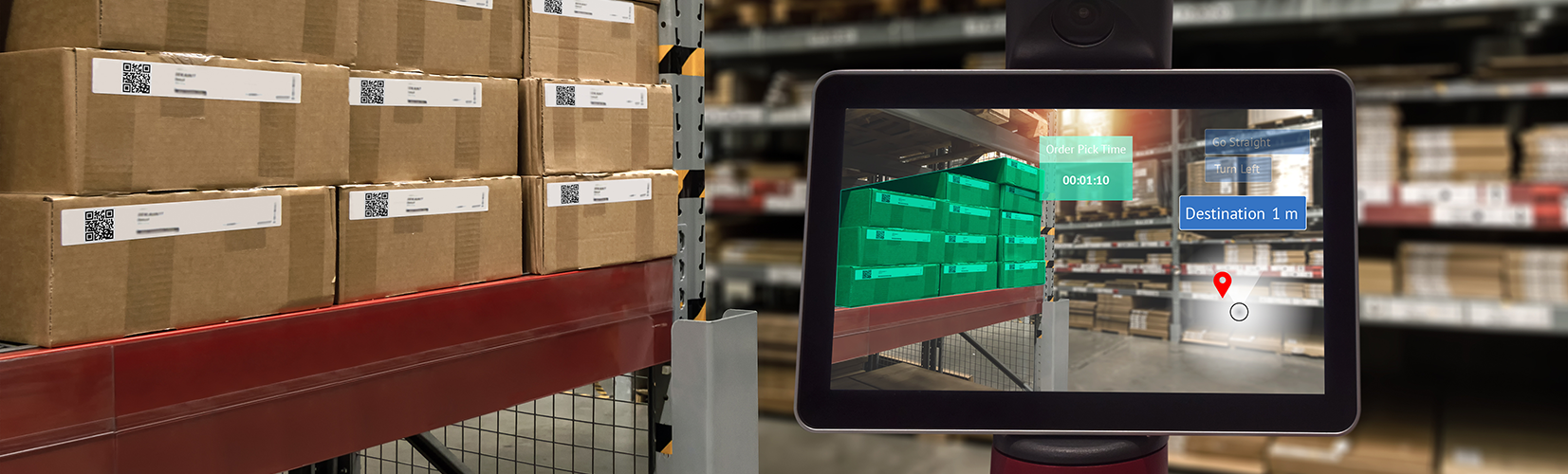

Granular data allows companies to “peek under the hood” and see what’s happening in their operation. In the world of packaging and distribution, this enables the tracking of information such as picking time, packing time, material consumption, and delivery time.

Most of this information can be gathered by scanning a barcode when each step of the order fulfillment process is completed, displaying it to managers in real time. The only limit to data is in a company’s collection protocols.

Improved Efficiency

Increasing supply chain visibility makes companies more aware of how they’re performing. You can’t improve what you don’t measure, and the data and automation-driven revolution (dubbed the “4th industrial revolution”) arms companies with the information they need to make adjustments and increase efficiency. After all, Forbes reports that embedding supply chain analytics in an operation can improve order-to-cycle delivery times by 4.25x.

Increased Profit Potential

When inefficiencies are addressed, it lowers costs and frees up resources, so companies can generate more revenue. Amazon famously created one-day shipping by working with manufacturers to track inventory. The data allowed them to locate warehouses closest to vendors and customers, shipping orders from the nearest and most convenient locations to meet the tight fulfillment deadlines. This decreased costs per order by a whopping 10 to 40 percent.

Bringing Big Data to the Packaging Floor

Automated and semi-automated packaging systems don’t just improve efficiency — they provide a simple way to bring supply chain analytics down to the machine and employee level.

Pregis’ Easypack® On-Demand Paper Packaging, Sharp® Poly Bagging, and IntelliPack® Foam-in-Place systems integrate well with existing smart supply chains at distribution centers and factories, laying the groundwork for a full data-driven operation. Each of them is equipped with the Maxwell™ Intelligent Interface, taking semi and fully-automated packaging to the next level.

The Maxwell™ Intelligent Interface allows users to fully customize each machine to their preferred settings, while connecting them to the big data “smart features” that allow greater packaging process control. The array of benefits include:

Data Analytics & Smart Settings

Maxwell-enabled machines allow users to track a number of metrics, including material consumption, cost per pack (calculating both supplies and labor), and employee and machine performance. These machines can improve and track sustainability metrics, too. Each can be programmed to sleep and conserve energy when needed and track electricity use, so managers can refine protocols to meet their eco goals.

Virtually Unlimited Memory

The Maxwell™ system allows users to customize machines for a near-limitless number of SKUs. Users can pre-program the IntelliPack® SmartBagger™ to dispense the right amount of foam for each type of product that comes down the conveyor belt. This type of automation speeds up the packing process while mitigating material waste. Best of all, these settings can be exported to all machines on the packing floor.

Intuitive Touchscreen Interface

Maxwell™ turns packing equipment into smart machines, with easy-to-navigate menus and customizable features. Customers can program machine-specific or floor-wide preferences, select settings for different SKUs, and read reports on the metrics they want to track. The interface can provide training on demand by displaying step-by-step pictures and videos that guide employees through specific packing procedures.

Pregis’ Easypack, Sharp Poly Bagging, and IntelliPack systems offer high-level data and insight that manufacturers and distributors can use to improve operational efficiency, lower costs, and gain an edge on their competition.

Do you want to see how these Pregis solutions can integrate with your existing data-driven supply chain? Or, are you looking to set up an intelligent fulfillment center but don’t know where to begin? Contact us today for assistance in setting up or revamping your operation.