Protective Film for Metals

Pregis offers the first domestic portfolio of universal laser film solutions, which offer metal service centers and fabricators cost-competitive, reliable protection. And our applications don’t stop there. Pregis has low-density films that can be cut, punched, and bended easily while still adhering to the protected surface. Our proprietary “A” film has superior puncture and abrasion resistance for roll forming operations. In addition, we have films that can handle high heat and are UV resistant for extended outdoor use with no adhesive transfer. Our solutions work on many different metals, such as steel, aluminum, pre-painted sheets, pre-coated sheets, uncoated sheets, and corrugated sheets. Choosing the proper temporary protective film ensures that polished metal surfaces are protected throughout fabrication, storage, assembly, and shipment.

Applications

Aluminum (Uncoated)

Aluminum (Anodized)

Aluminum (Satin)

Aluminum (Mirror Finish)

Stainless Steel (Matte Finish)

Stainless Steel (Brushed Finish)

Stainless Steel (Mirror Finish)

Stainless Steel (Deep DRW)

CO2/Fiber Laser Cutting

Pre Painted Metals/Sheets

Steel

Laser Cutting

High Structured Metal Sheets

Profiles

Corrugated Sheets

Roof Panels

Siding Panels

Protective Film Capabilities

| Films and Coatings | Converting & Options |

|

|

|

|

|

|

|

|

| Key Product Options | |

| “A” Films: Our proprietary film offers a unique combination of advantages | |

|

|

|

|

|

|

|

UV resistant films available for added surface protection for extended outdoor applications. Options include 3, 5 or 9 month protection against UV degradation. |

|

Material Need & Product Number (Coated: 2A825C) |

|||||

|

Textured Surface: |

High Textured Surface: |

High Structured Metal: |

High Gloss Paint: |

Appliance Coatings: |

UV Exposure: |

Material Need & Product Number (Uncoated: 21825C) |

|||||

|

Diamond Plate: |

Textured Metals: |

Mirror Finish: |

Annealed Surfaces: |

Forming: |

UV Exposure: |

The First Domestic Portfolio of Universal Laser Film Solutions

Our strippable laser films are expertly designed to reduce your total cost of ownership within your laser cutting and metal fabrication operations. A typical fiber laser concentrates 3-4 kW of energy to an area smaller than a human hair. This equates to a power density 100x that of the sun. Without surface protection, laser cutting can cause significant collateral damage to aluminum and stainless steel, translating to costly rework, or worse, material scrap. On top of these added expenses, damages contribute to operational downtime, ultimately reducing your ability to get product out the door to critical customers.

The Perfect Balance of Performance

Our high-quality solvent adhesive chemistries and durable films lead the market in laser cut quality and cleanliness.

- Strong tack to ensure ease of application

- Unparalleled adhesive strength keeps film firmly in place – without blow-ups

- Effortless removability, free of ghosting or adhesive transfer

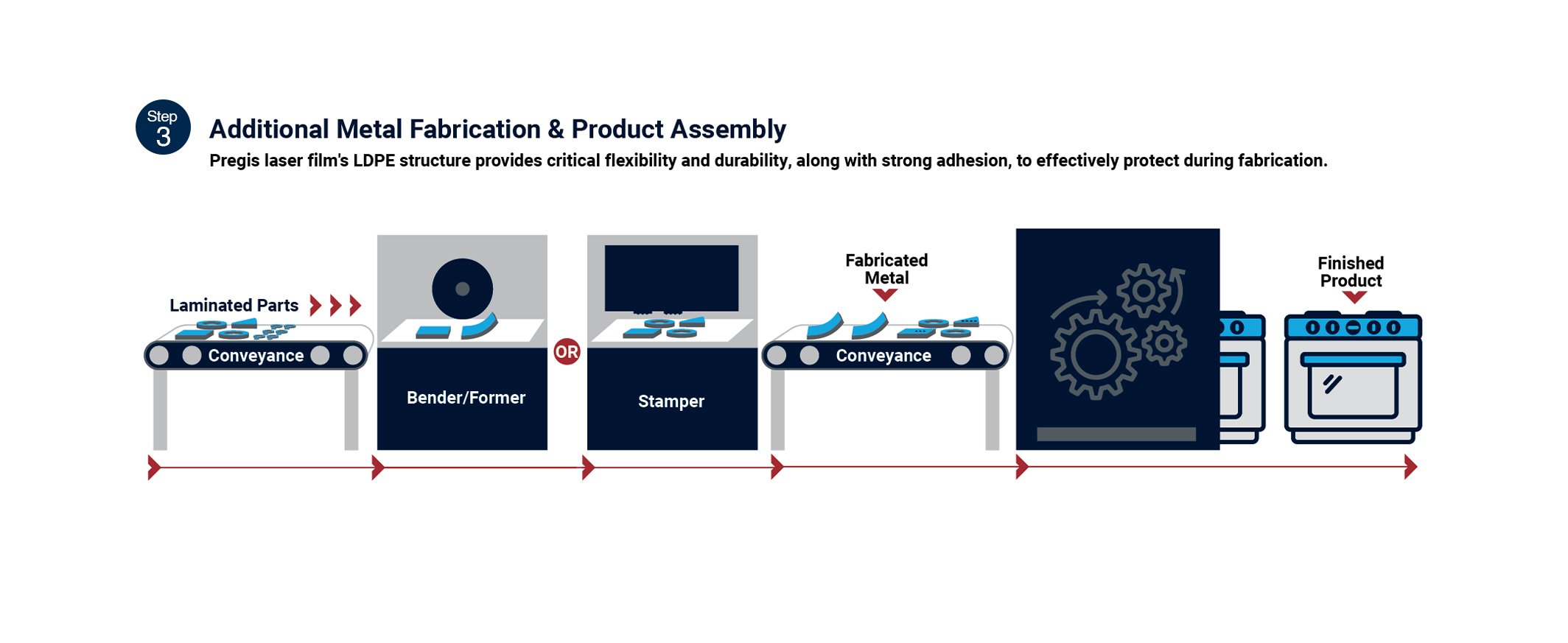

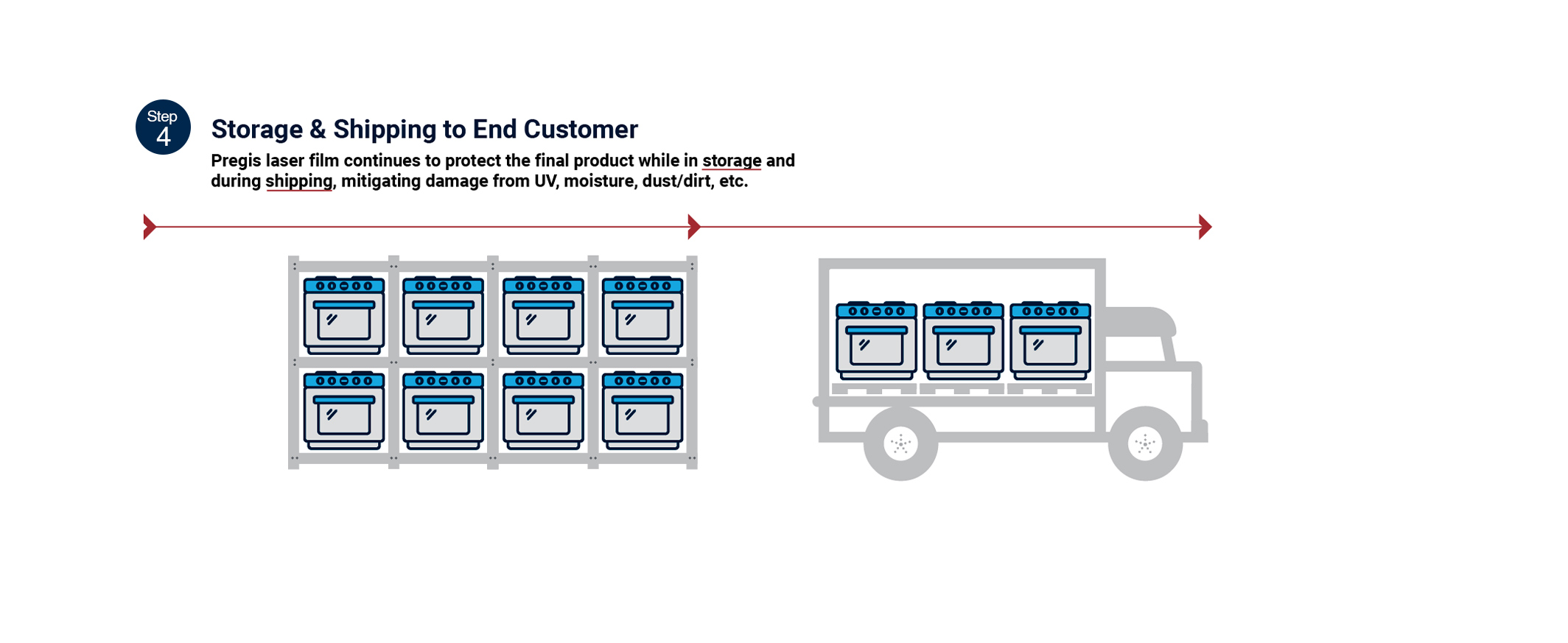

- Versatile downstream protection, from bending/forming to shipping and storage

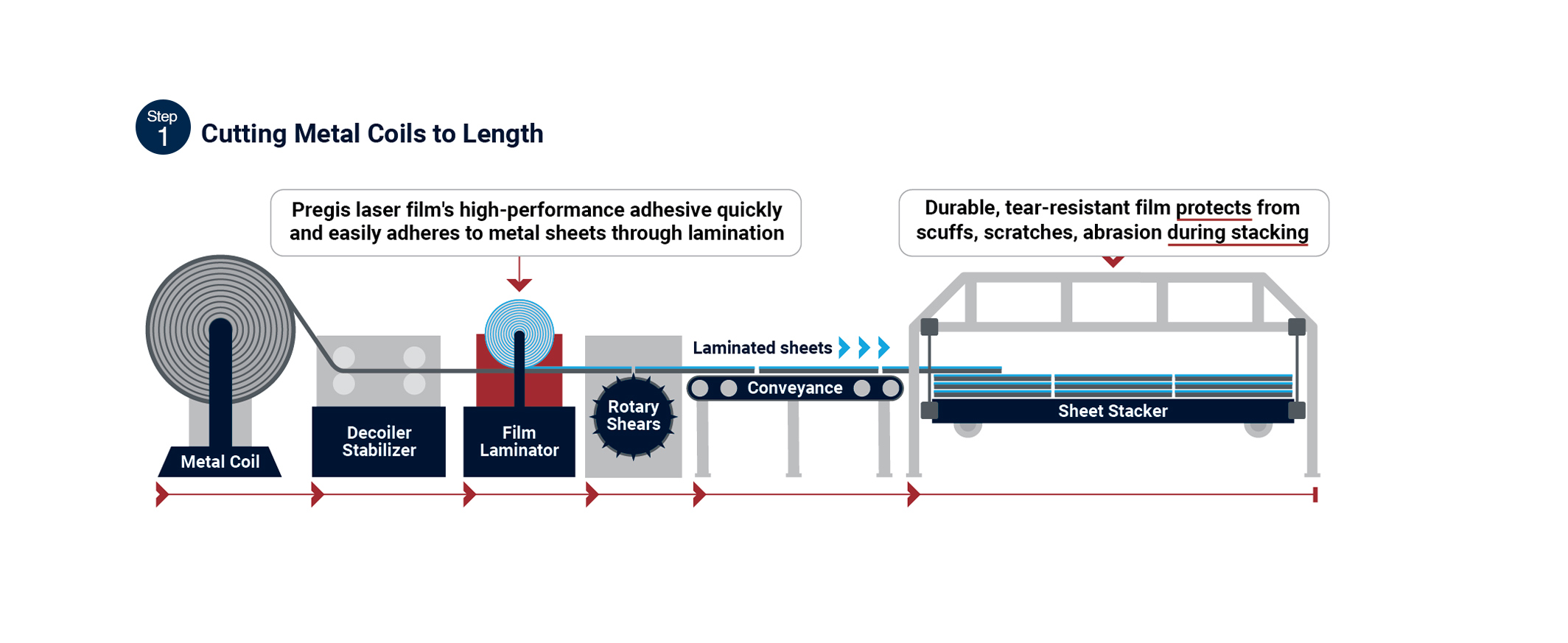

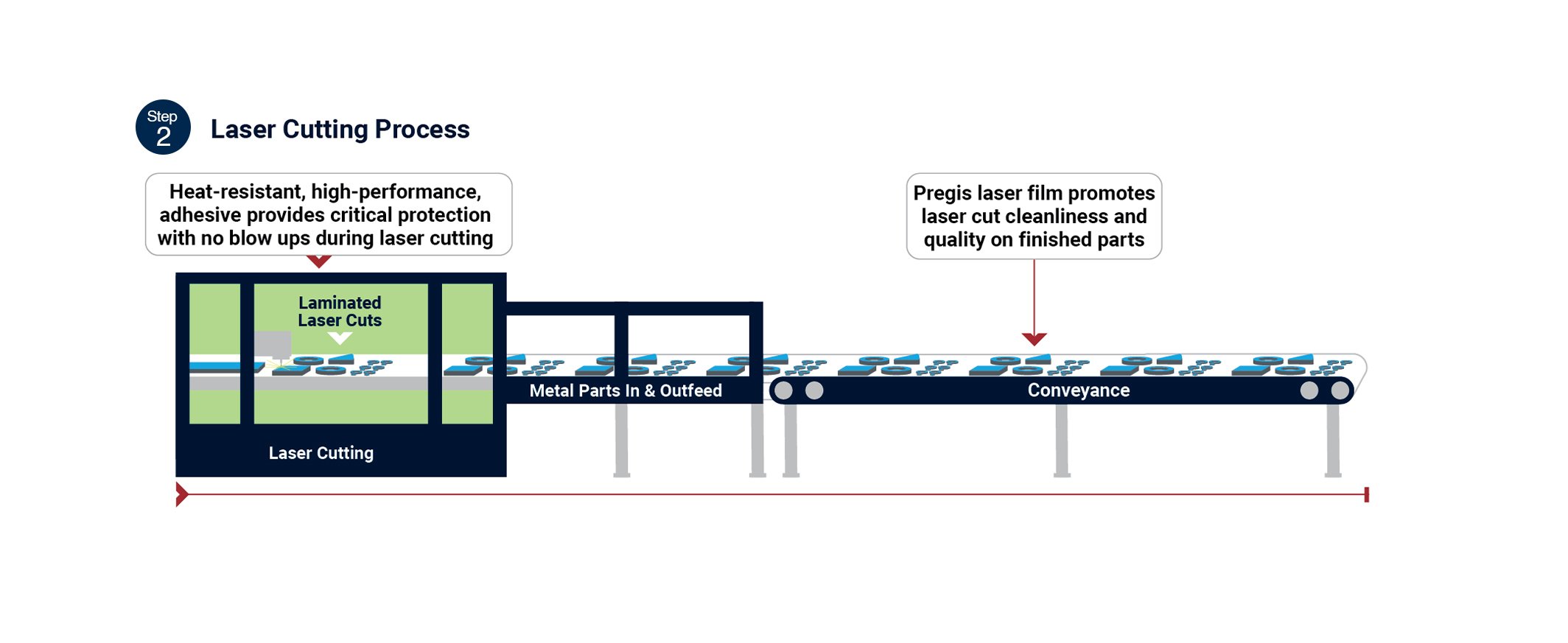

Pregis Laser Film Protects Your Metal Throughout Your Operation Check Out Its Benefits At Every Step Of The Way

Related Articles