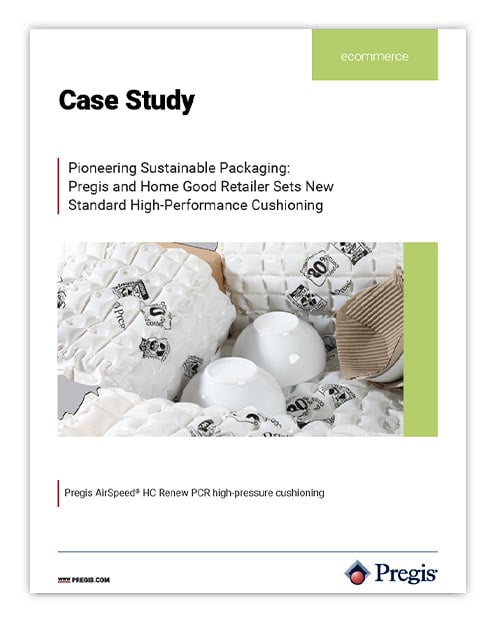

Pregis and a high-end home goods retailer embarked on a an innovative collaboration in sustainable packaging, marking a significant chapter in their decade-plus-long partnership. The culmination of this effort is on-demand solution: Pregis AirSpeed® HC Renew PCR high-pressure cushioning.

Overview

Overview

Pregis and a high-end home goods retailer embarked on a an innovative collaboration in sustainable packaging, marking a significant chapter in their decade-plus-long partnership. The culmination of this effort is on-demand solution: Pregis AirSpeed® HC Renew PCR high-pressure cushioning.

Challenge

The retailer aimed to transition all plastic packaging to materials containing at least 80% post-consumer recycled (PCR) content within a year. Protective packaging is critical in maintaining the brand’s product integrity, especially for fragile items like glassware. Meeting the PCR requirements while manufacturing a thin-gauge high-pressure film capable of protecting these delicate items presented a unique challenge for Pregis.

Solution

Material Selection and Quality Assurance

The lack of existing solutions that met the sustainability and performance criteria presented a significant barrier. Pregis skillfully navigated this challenge by conducting a comprehensive market analysis to identify cost-effective, high-quality PCR resin sources. They selected a PCR blend from a reliable stream with low contaminant levels, ensuring steady access and quality assurance.

Use the form on the right to download the full case study!